Marine loading arm systems serve a vital role in the safe and efficient transfer of bulk products between vessels and shore-based facilities. These complex mechanical systems comprise articulated arms, valves, and control systems designed to ensure a seamless flow. A comprehensive guide to marine loading arm systems should cover key aspects such as design principles, deployment, operational guidelines, maintenance requirements, and industry standards.

- Understanding the diversity of marine loading arm designs is crucial for selecting the most effective system for a given scenario.

- Factors such as cargo type, flow rates, and environmental conditions must be thoroughly evaluated during the selection process.

- Proper setup of marine loading arms is essential for optimizing system safety.

Scheduled maintenance procedures are critical for ensuring the reliable operation of marine loading arm systems and mitigating potential risks.

Efficient Loading Systems for Streamlined Liquid Transfer

When it comes to seamlessly transferring liquids in industrial settings, top loading arms play a essential role. These versatile systems offer a trusted method for dispensing fluids with accuracy. Top loading arms are designed to eliminate spills and improve workflow, facilitating to a more efficient operation.

- Benefits of top loading arms include:

- Reduced risk of spills and accidents

- Improved accuracy

- Streamlined process

- Customizable configurations

Ensuring Safe and Secure Cargo Offloading

Bottom loading arms play a crucial role in the safe and reliable offloading of cargo from vessels. These advanced pieces of equipment are designed to transfer bulk materials seamlessly from a vessel's hold to storage facilities or trucks.

To ensure safety during this process, bottom loading arms are fitted with a variety of protective mechanisms. These comprise pressure regulators, temperature monitors, and automated shutoff valves.

Furthermore, bottom loading arms are designed to tolerate the challenges of industrial operations, ensuring they stay reliable and functional over time.

By implementing rigorous inspection schedules and adhering to industry safety protocols, businesses can optimize the efficacy of their bottom loading arms, ensuring a safe and secure cargo offloading process.

Enhancing Marine Operations with Loading Arms Technology

Loading arms play a crucial role in guaranteeing the effectiveness of marine operations. These cutting-edge technologies allow for loading arm seamless transfer of products between vessels and shore installations. By reducing the risks associated with manual unloading, loading arms facilitate a safer and more trustworthy operational environment.

Additionally, advancements in loading arm design have led to optimized performance, including higher transfer rates and lower energy usage. This produces in significant cost benefits for marine operators.

Integrating loading arms into current marine infrastructure can dramatically improve operational effectiveness, in conclusion contributing to a more environmentally responsible and profitable maritime industry.

Types and Applications of Marine Loading Arms

Marine loading arms serve the safe and efficient transfer of products between vessels and shore-based facilities. These specialized devices are designed to withstand the harsh maritime conditions prevalent in ports and offshore platforms. There are numerous types of marine loading arms, each suited for specific applications:

- Rigid Loading Arms: These arms provide a solid connection between the vessel and the shore facility, offering high volume for large-scale operations.

- Swiveling Loading Arms: Designed to adjust to movements of both the vessel and the platform, these arms offer flexibility in alignment.

- Underwater Loading Arms: These specialized arms are installed beneath the water's surface, facilitating the transfer of products from underwater facilities or pipelines.

Marine loading arms play a essential role in diverse sectors, including:

- Oil and gas: Transferring crude oil, refined products, and natural gas.

- Chemical manufacturing: Handling corrosive chemicals, solvents, and bulk materials.

- Food and beverage: Loading and unloading commodities in ports and processing facilities.

The Importance of Maintenance for Loading Arms in Maritime Industries

Loading arms play a vital role in the efficient and safe transfer of liquids between vessels and shore facilities within the maritime industry. Regular maintenance proves to be indispensable for ensuring the longevity, reliability, and safety of these crucial pieces of equipment. Neglecting maintenance can lead to deterioration of loading arms, resulting in costly repairs, operational disruptions, and potential risks.

A comprehensive maintenance program should encompass audits at regular intervals, coupled with prompt repairs to address any identified issues. This methodology helps to minimize downtime, reduce operational costs, and ultimately optimize the overall safety and efficiency of maritime loading operations.

ul

li Maintenance should be documented and recorded for future reference.

li Qualified technicians should be employed to perform maintenance tasks.

li Loading arms should be inspected for signs of wear and tear, corrosion, or damage.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Alfonso Ribeiro Then & Now!

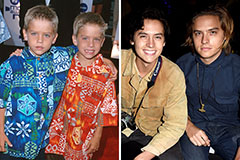

Alfonso Ribeiro Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!